ASTM A532 White Cast Iron Bimetallic Standard Shaped Wear Bar for Mining Wear

Model No.︰-

Brand Name︰Hyster

Country of Origin︰China

Unit Price︰-

Minimum Order︰100 kilograms

Product Description

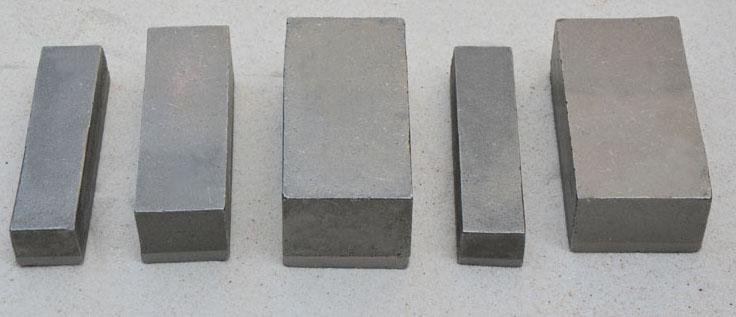

ASTM A532 White Cast Iron Bimetallic Standard Shaped Wear Bar for Mining Wear

1) Main material:

Cast Iron (≥63HRC/700BHN,wear resistance) + weldable mild steel(impact resistance)

2) Wide applications:

Abrasion solutions for industrial equipment or tools: bucket,loader, excavator,dragline,G.E.T. tools,hopper,crusher,feeder, etc

3) Advantages:

Better wear resistance performance, Durable, Cost effective, Excellent quality, Good service

4) Chemicals:

| C | Cr | Mn | Mo | Cu | P | Si | S | B,V,Nb |

| 2.5-3.5 | 15-18 | 0.5-1.5 | 0.5-2.5 | 0.5-1.0 | 0.02max | 0.5-1.0 | 0.02max | 0.1-0.5 |

The unique, formable design of Hyster-Wear chocky bars are available in various lengths, grades and sizes and can also be customized as per the clients specific need.

Applications for Chocky Bars are wide and varied, ranging from specific wear protection on buckets for loaders, excavators and draglines machines, or for weld-on hammer tips for the re-cycling industry, or chute linings and rock box edges.

They are easy to use and install. They can be bent, cut and formed to suit different surfaces.Chocky bars can be formed onto inside or outside contoured surfaces to provide an extra level of protection for wear and impact applications.

We can also produce according to your special requests.

Some of our products and services:

-----Wear plates, wear liners

-----Chocky bars and wear buttons

-----Wear blocks, wear bars

-----Custom made wear liners

-----Bucket repair and protection

-----Full Fabrication services

-----Sugar mill hammer tips

-----Drilling, milling or machining

-----Casting/Investment casting

-----Fast service and timely delivery

| A. Mechanical Property | ||||||||

| 1) Tensile Strength : | 630Mpa Min. | |||||||

| 2) Shearing Strength : | 250Mpa Min. | |||||||

| 3) Hardness : | 63 HRC | |||||||

| B. Micro-structure | ||||||||

| Carbide + Martensite + Retained Austenite, the carbide content is about 41.4% | ||||||||

| Contact: | ||||||||

| Bonnie Deng | ||||||||

| Cell: 86-189-4254-3248 | ||||||||

| Email: sales02(@)hystertech.com | ||||||||

| Skype: bonniedeng.hyster | ||||||||

| www.hystertech.com | ||||||||

| www.hystertech.en.alibaba.com | ||||||||

Payment Terms︰ TT/ LC

Product Image